AquaSafe HM 2.5

AquaSafe HM 2.5 Confined Space Cleaner is a specialty product formulated for surface cleaning prior to painting in confined space areas where worker safety is of the utmost importance. This unique blend is designed to eliminate the need for using dangerous solvents in confined space areas. Having no HAPS or VOC’s, AquaSafe™ HM 2.5 is the product of choice for safety and environmentally conscious owners and paint superintendents.

Being non-flammable, biodegradable, and having a fast evaporation rate, AquaSafe™ HM 2.5 is safe, easy to use, and eliminates the most common dangers to the operator when cleaning confined space areas for painting. AquaSafe™ HM 2.5 is not just a pre-paint cleaner, but it also has the benefit of helping to prep the surface for superior paint adhesion.

Our Customer’s Story:

“I just wanted to give you heads up on the AquaSafe™ HM 2.5 cleaning results. We are very satisfied with the product, as it saves me a lot of time and effort. The best part is that it’s non-flammable and I can actually clean as hot work is going on, which saves us a lot of time. This helps me stay on schedule to get the job done! I’m one satisfied customer! I would recommend this product to anyone.”

-Shipbuilder— Houma, LA

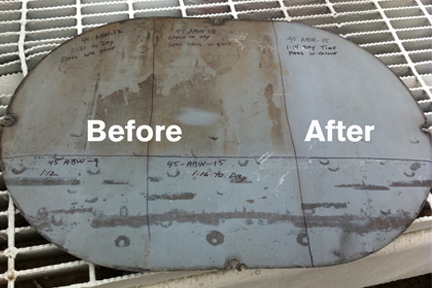

Testing done by KTA Tator, Inc., an independent lab, confirmed that AquaSafe™ HM 2.5 removed all visible oil, grease, and soils from steel surfaces therefore leaving the metal clean by SSPC-SP1 standards.

“Laboratory testing involved contaminating blast cleaned panels with a range of materials listed in the sample section, including hydraulic oils, cutting oils and heavy duty drawing compound. After cleaning with an AquaSafe™ HM 2.5 saturated cloth, the visual evaluation revealed that the resulting surfaces were consistent with the definition of a solvent cleaned surface. There was no visual evidence of any of the compounds used to contaminate the surface remaining on the panels. As an additional test and to verify the visual cleanliness, the cleaned surfaces were coated with the supplied primer labeled, “Paint 175/176 (International Interzinc 52).” The panels did not undergo any additional cleaning beyond the wipe with the AquaSafe™ HM 2.5 followed by a wipe with a clean, dry towel to remove any lint or other residue from cleaning. The adhesion values generated by the contaminated panels were then compared to the adhesion values generated by the control panels, which did not have any of the contaminants applied. The comparison revealed that the adhesion values of the contaminated panels were comparable to the adhesion values of the control panels, indicating that the adhesion of the primer to the panel was not being adversely affected by the presence of a contaminant remaining on the surface.”

-Valerie D. Sherbondy, Senior Chemist

Request a complete copy of the KTA Labs test results.

For more information contact a Customer Service Representative or email sales@researchsolutionsgroup.com.